FOR FLEXIBLE OFFLINE-TO-RUNNING

MEASUREMENTS OF CRITICAL MACHINES

Measurements of dynamic movements are used for critical machines within industries,

where large temperature differences or other disturbing factors exist. The

need for measurement of dynamic movements is often indicated by a high level of

vibrations. For some machines these high levels remain even after having performed

shaft alignment in cold condition. The Fixturlaser NXA together with the OL2R

Expansion kit helps you to overcome this costly and time consuming problem by

performing offline-to-running measurements. The measurements provide you with

machine unique target values to be used for compensation during shaft alignment.

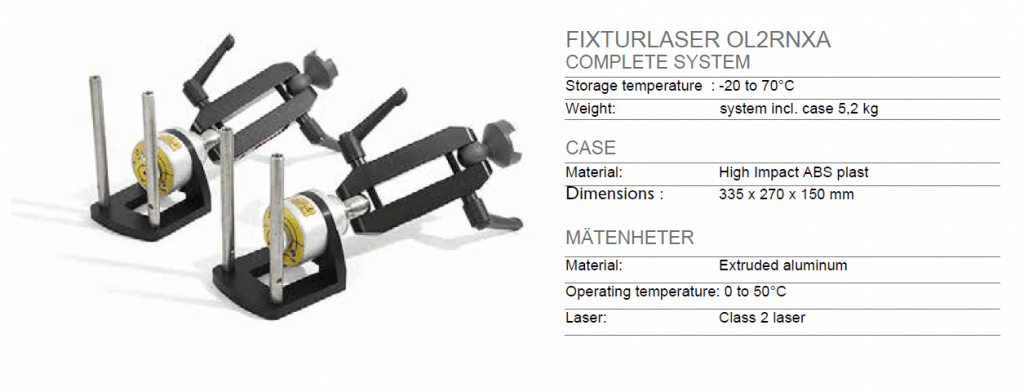

The Fixturlaser OL2R Expansion kit consists of both software and fixtures.

The Fixturlaser OL2R fixtures are both equipped with a laser pointer, which means

that the Fixturlaser NXA alignment system is not needed in order to mount the

fixtures. Thanks to this feature the mounting can be performed fast and easy.

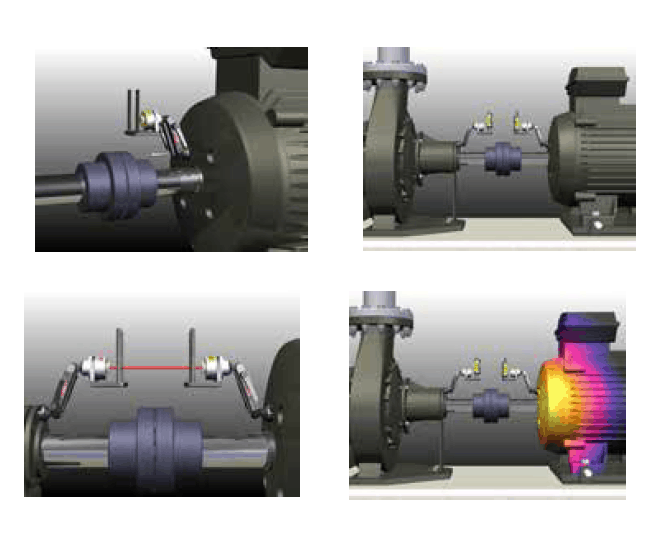

The offline-to-running measurement

process in short

Mount the tooling ball on each machine. Ensure

that the bolt is tighten and that the arrangement

is firmly mounted to the machine casing.

Check that the laser is adjusted to the rotational

centre by rotating the turret on each fixture.

Adjust the fixtures until both the lasers are hitting

the centre of the opposing target. Tighten

the screw on the fixture and make sure that it

is stable while rotating the turrets.

Turn off the laser beams in the fixtures and mount

the Fixturlaser NXA sensors on the posts of the

fixtures. Set the sensors so that they are approximately

at the same rotational angle when taking

the three measurements. Perform the measurement

in both cold and hot condition. Thereafter

continue with the shaft alignment using the target

values from the offline-to-running measurements.